In today’s competitive market, the cost of production determines the output of the company. The earnings of the industry are quite volatile. The smallest factor can have a significant impact on your net profit. The problem is that you have to keep the cost at par with the market price.

However, the manufacturer cannot compromise the quality of the merchandise.

The technologies which we employ in the industry continue to evolve, giving us an increase in yield. They can reduce both the cost and the energy which the industry spends on the manufacturer. The food industry needs such solutions as other businesses it operates to earn more profit.

Don’t Miss:-Different industrial valves and there best applied

Here are some tips to save energy in food processing plants

1. Location

The location of the plants is essential for it to save energy. There are many vital aspects that determine the energy input. If the industrial unit is in a warm place, then the food products will require constant cooling. The factory will need central heating or cooling to regulate the temperature continuously.

The cost of energy sources such as electricity and fuels will determine how much power you use. Moreover, if the demand for food products is tremendous in a particular place, it makes sense to open a processing unit in that area.

2.Trained Labor

The energy consumption of the plant can also be made efficient by the labor. They will be careful of the fact that all the machinery work efficiently, so they do not use extra energy. The skilled worker will be able to perform the task in a given time frame and perimeter.

The management should conduct regular training exercises for the workers so that they may be aware of any discrepancies in the process. The advantage of such activity is that it allows workers who are unable to handle the devices correctly to correct their mistakes.

The management can employ different methods to increase the productivity of the workers. It will encourage the employee to take more interest in saving the resources for the company.

3.Streamlining Design

The food processing plant has to meet specific criteria for it to operate. The industrial unit gets orders which it has to fulfill. To satisfy the consignment, the plant works to make them as quickly as possible. The process can take a lot of energy to operate at peak efficiency. However, the design of the can prevent waste of power in a lot of places.

The management can hire architects and engineers who can redesign the whole process to streamline it for efficiency. It will help in achieving all the goals properly. The design optimization will also be cost-effective. The decrease in energy expenditure will increase profits.

4.Proper Equipment

The energy-efficient equipment can help you save up a lot of power when operating them. The machines in food processing plants use up a lot of energy. It makes sense to adopt the latest innovation in the machinery. The plant can buy condensers and refrigerating units that use less electricity to produce a better result than the older models.

The equipment has to use proper pipe systems, which include pipes, valves, and delivery mechanism. If the pipes and valves are not up to the specification, the liquid or semi-liquid food can get stuck. It will cause not only delays in the production but also result in the waste of a lot of energy.

The food processing plant will have to use a good check or butterfly valve for its equipment needs.

5.Recycling

The plant can save energy by recycling the products; they can use different materials that have been in use once before as well. The end product will require less energy as most of its component will be already completed. The plant can adapt cheaper materials made from products like old paper and plastic and metal cups.

6.Employing Energy Efficient Systems

The new and latest technologies are very energy efficient as they consume less electricity to do the same job. If the desire is to increase the output but decrease the energy input than the system requires an update. The management has to consider investing in equipment which will increase its energy efficiency, such as using industrial LED lights on elstarled.com .

7.Computerization

The whole process takes some time to complete. If there are a lot of human interfaces, then each process can become very lengthy. An automated system will prevent any loss of time by streamlining the process. If you are looking for any discrepancy in the process, then the computer will help you find it faster.

If you have a computer interface in your plant, then all you need to do is enter the command, and the machines will do the rest. The computer system will do the rest, guiding the whole process according to its programming.

7.Sustaining Hygiene

The food processing plant can maintain a high level of cleanliness to prevent any contamination. A regular schedule of cleaning can prevent any impurities from finding a way into the equipment. In this way, the clean workstation can save us the time of stopping and reexamining the whole plant. The energy that you can spend on the main operation will instead go to waste.

The system needs to be flawless for it to work more efficiently. Thus, by maintaining a clean station, you can eliminate one obstacle that may hinder the process.

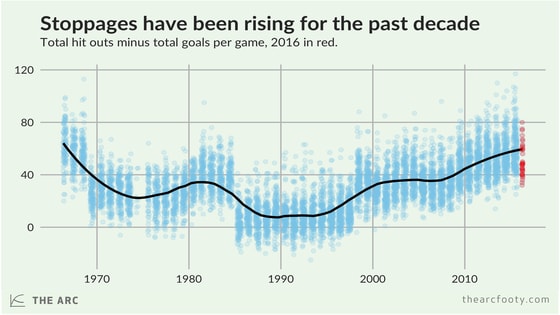

8.Reducing Stoppage

The company which operates the plant can plan the whole operation. They can work out all the kinks on paper. It will give them adequate time to work out the solution. It will show them exactly where and how the process may lag. The management can then take countermeasures to ensure the smooth sailing of operations.

Conclusion

The food processing plants are providing a vital service by packing fresh and raw food and making it available all year round for us. As a result, it has a significant market share. However, like all businesses, it requires a healthy profit to operate. The only way it can profit in the modern economy is by streamlining its processes and decreasing its costs. The food processing industry can employ different methods to save energy, thereby reducing costs.